Semicon & high purity components

What is this?

We design and manufacture a wide range of high purity components and process equipment for the semiconductor industry - all tailor-made to meet our customers’ needs.

Why use high purity components?

Keep chemical purity under ppb levels

We can keep the impurities below 150 ppt with respect to metal and ionic contamination. We use high purity PFA or PTFE for piping, valves and pumps, flared couplings. We ensure minimal dead spaces to reduce interference with high-purity chemicals to a minimum.

Chemical and heat resistance

Plastic materials are selected to meet high purity requirements as well as chemical and heat resistance. PFA, PTFE, ECTFE, FEP, PVDF, PP, POM, PEEK, and C-PVC are most commonly used, however, to meet specific safety standards we also work with FM4910 approved materials.

What options does Teblick offer?

Our product range for the semiconductor industry includes but is not limited to:

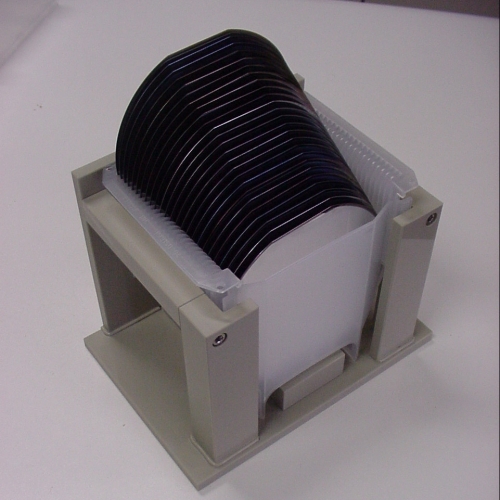

Wafer etching equipment; handling and inspection tools:

- Wafer tweezers and handlers

- Wafer cassettes

- Wafer trays

- Cassette inserts

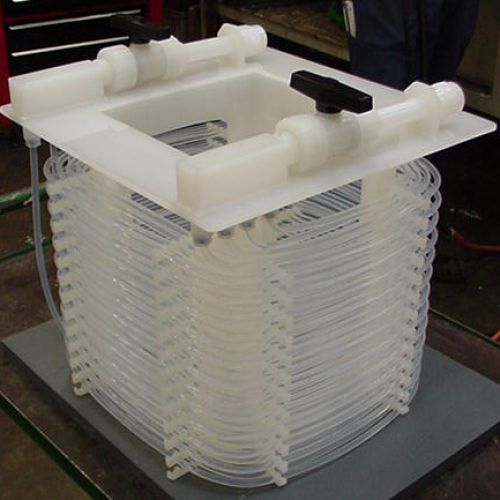

Process equipment:

- Chemical Distribution Units (CDU)

- Slurry Distribution Units (SDU)

- Wet benches for acid and caustic etching or cleaning processes

- Wet benches for solvent processes

- Chemical waste collection and handling equipment

- Quick dump rinse baths

- Laminar flow cabinets

- Chemical mixing and pumping stations

- Chemical blending equipment

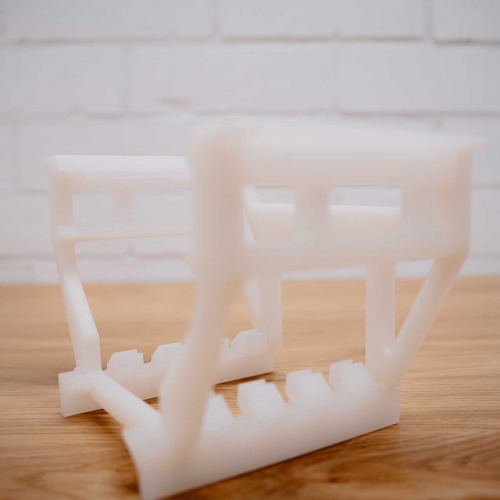

Machine Parts:

- Turntables

- N2 wet blanketing with bubblers

- Process tanks with heating, cooling, recirculation, and filtering

- Ultrasonic cleaning

- Mix tanks and vessels

- Rinse baths

- Quick dump rinse baths

- Valve manifolds

- Sensor housings

- Drum connectors and dip tubes